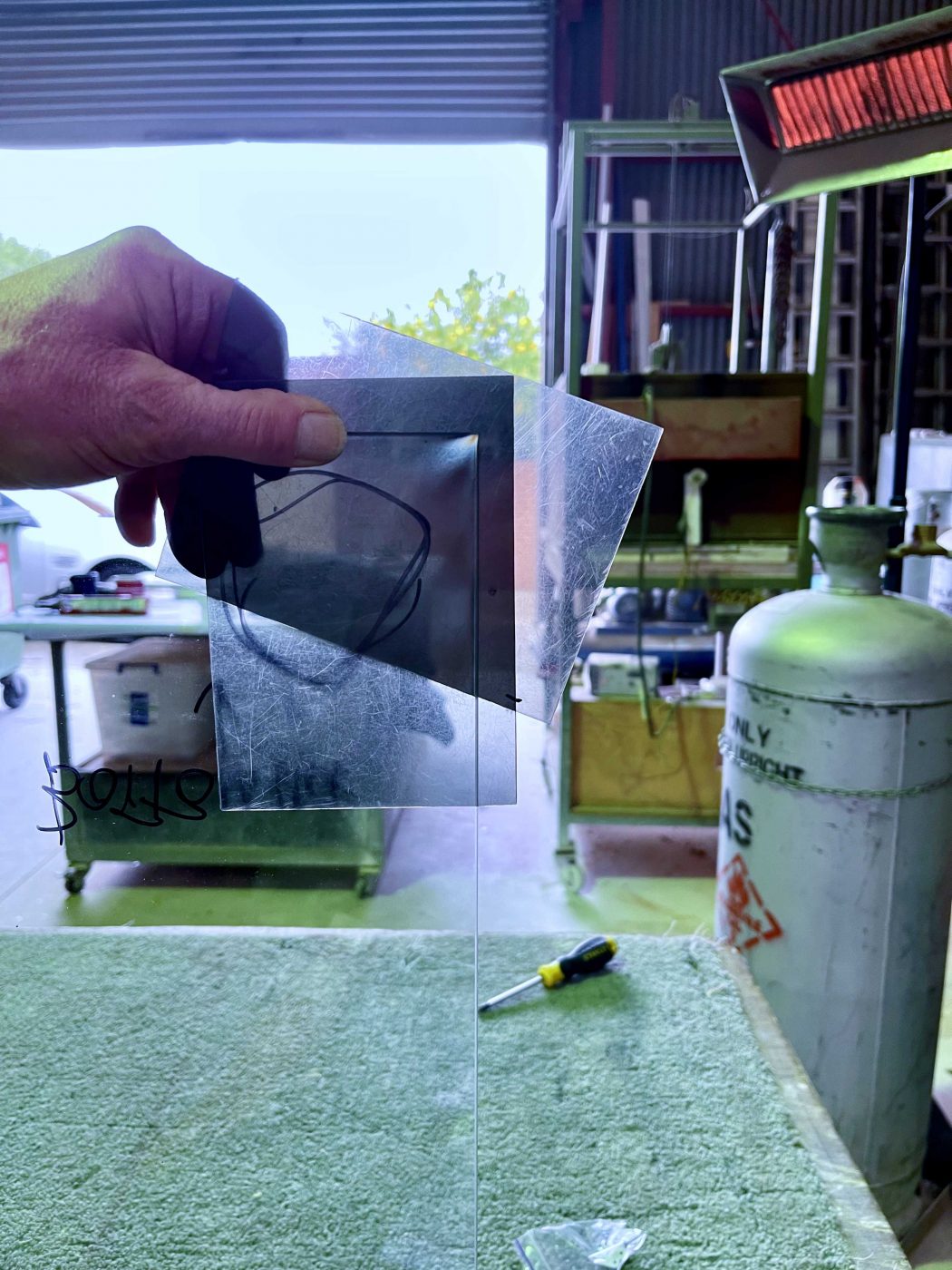

Repair or replace? My current water feature was taking in water between the glass and the coloured 2PAC hardened paint finish applied to the rear of the glass.

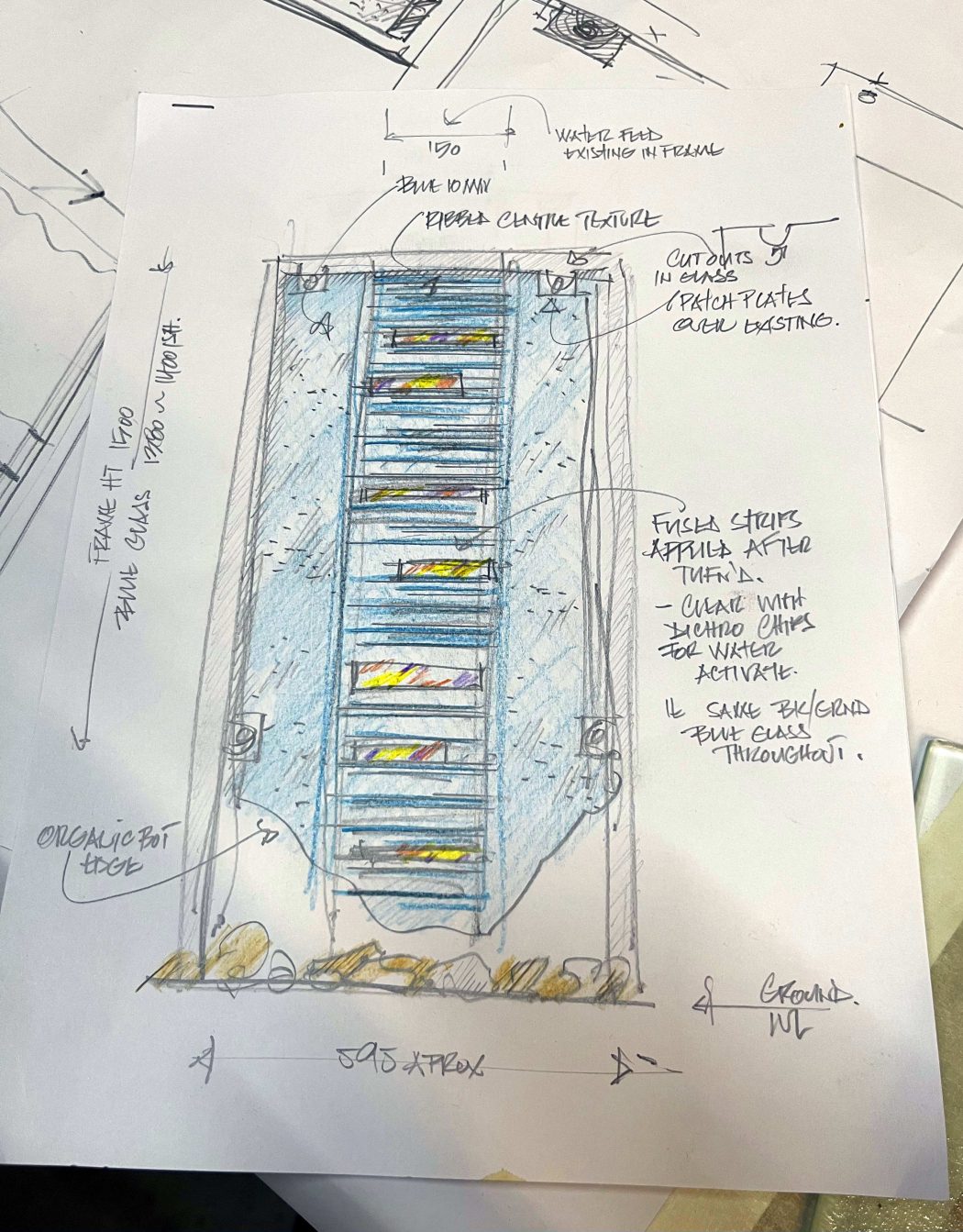

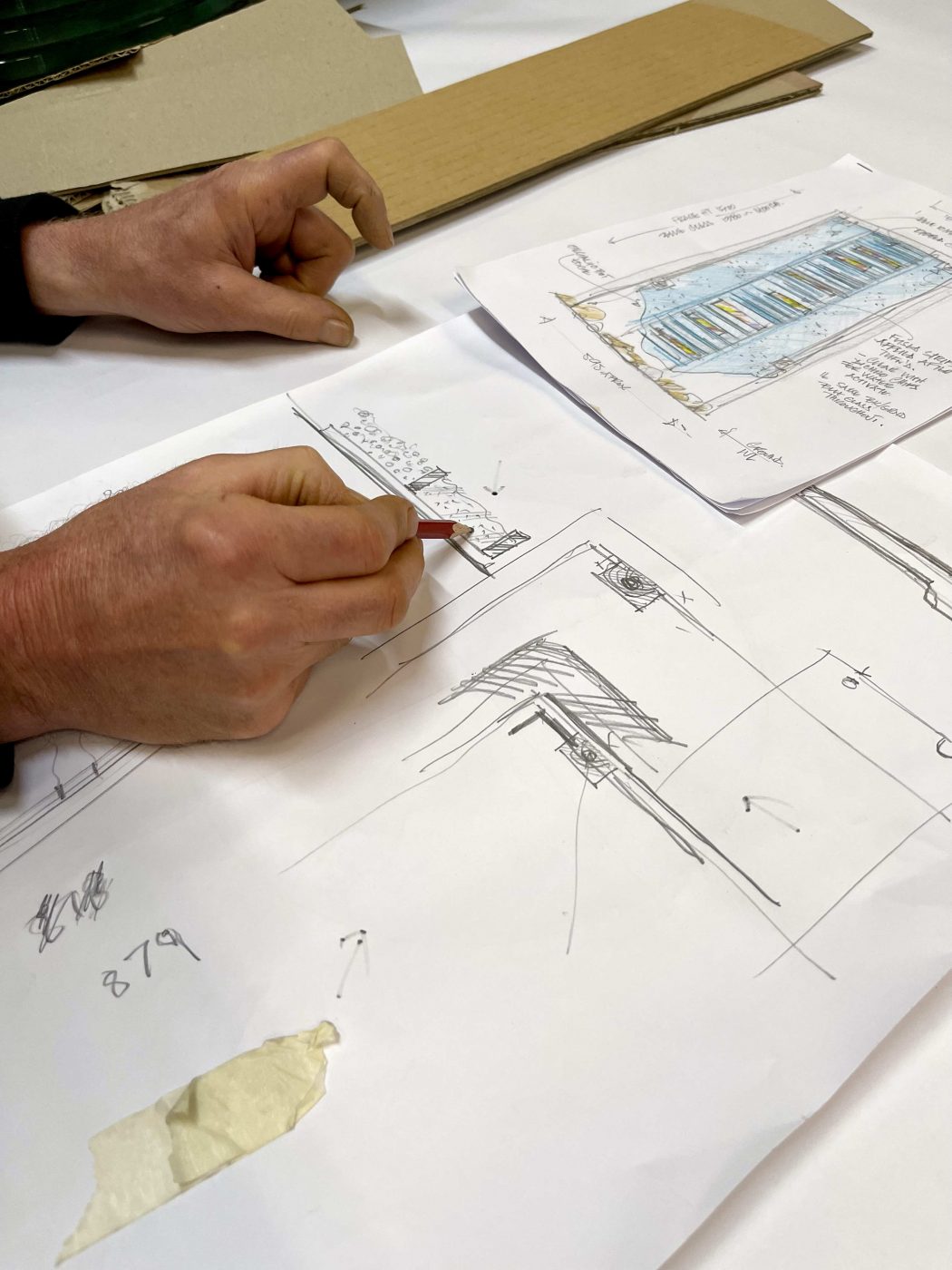

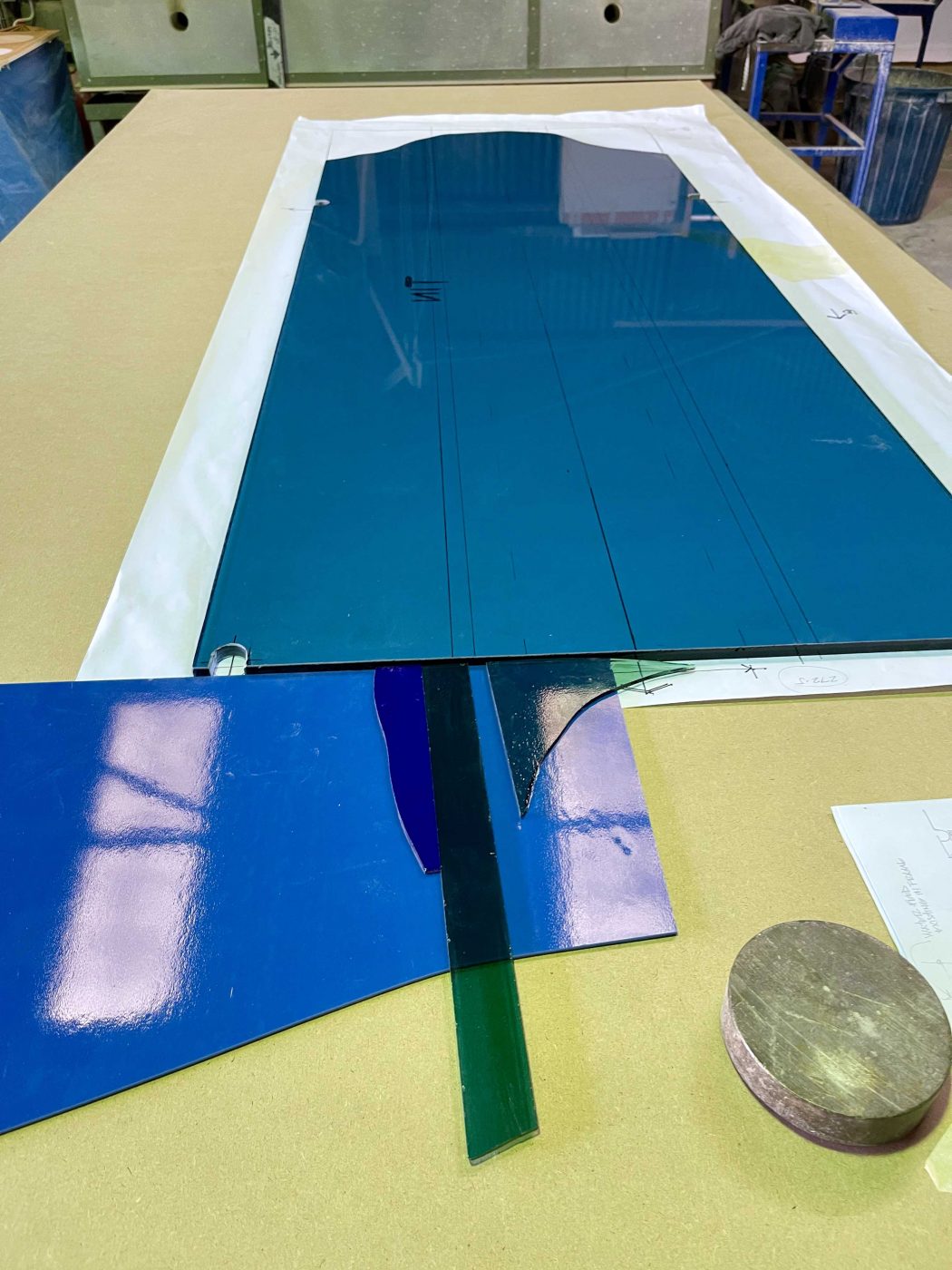

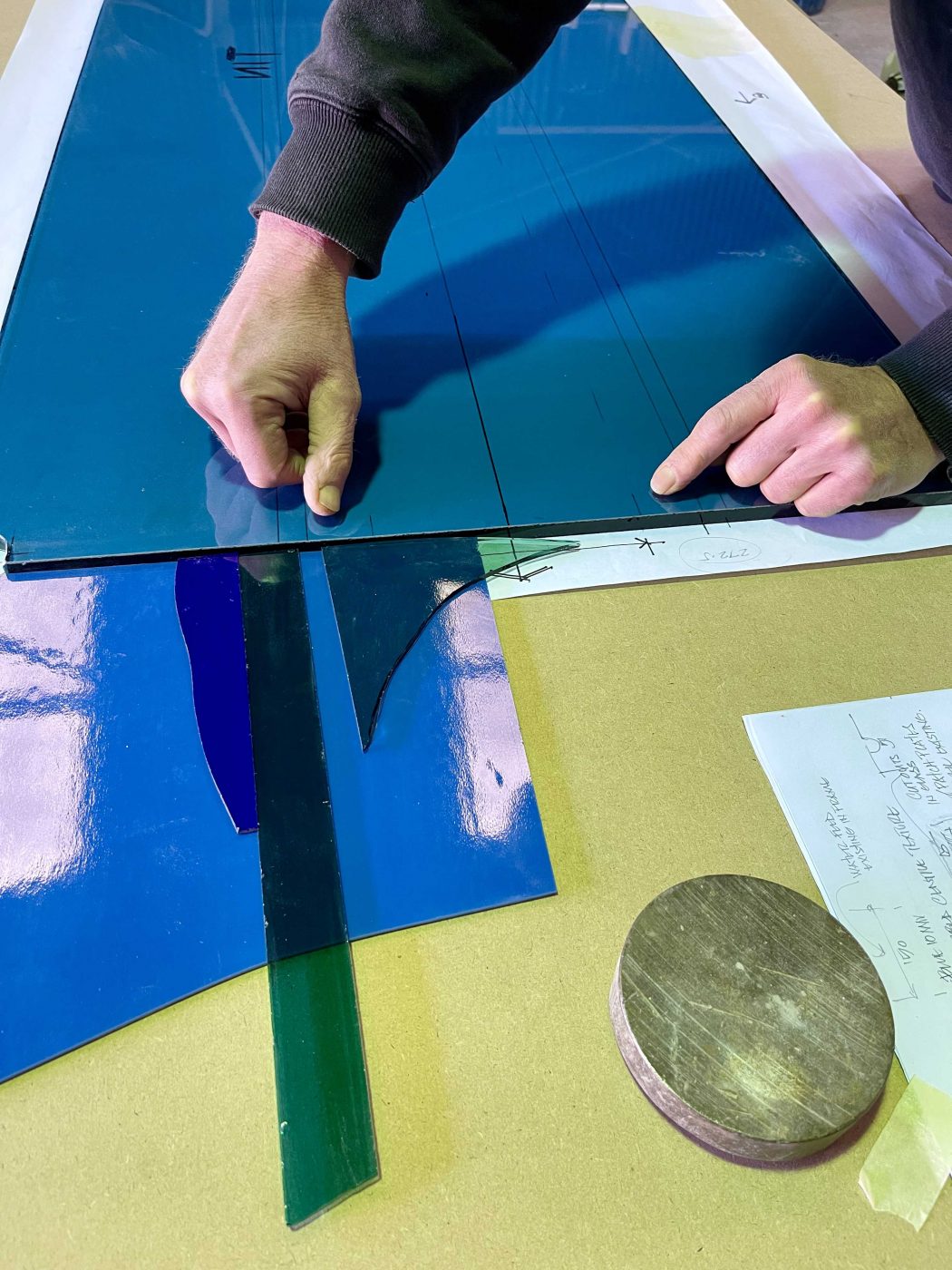

An extensive online search, found local guy, artist and designer extraordinaire Waynne Rayson at Toucan Forged Glass, whose skills encompass more than 35 years working with glass, both decorative and functional. My decision was to replace the glass utilising the space within the stainless steel frame rather than a single centred glass panel. This idea proved to be a bonus as the current stainless steel fittings, presenting as a feature rather than functional, would be eliminated.

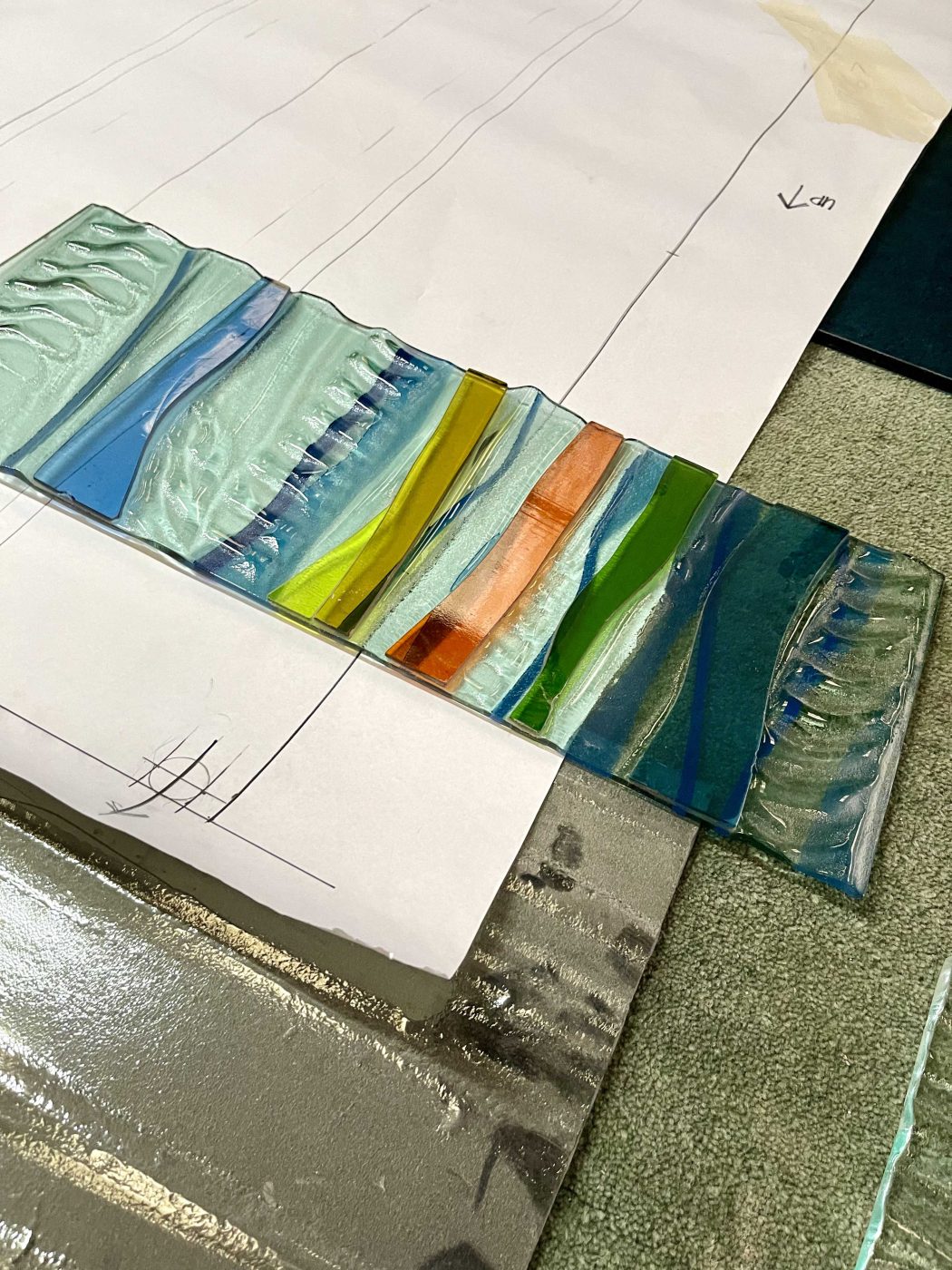

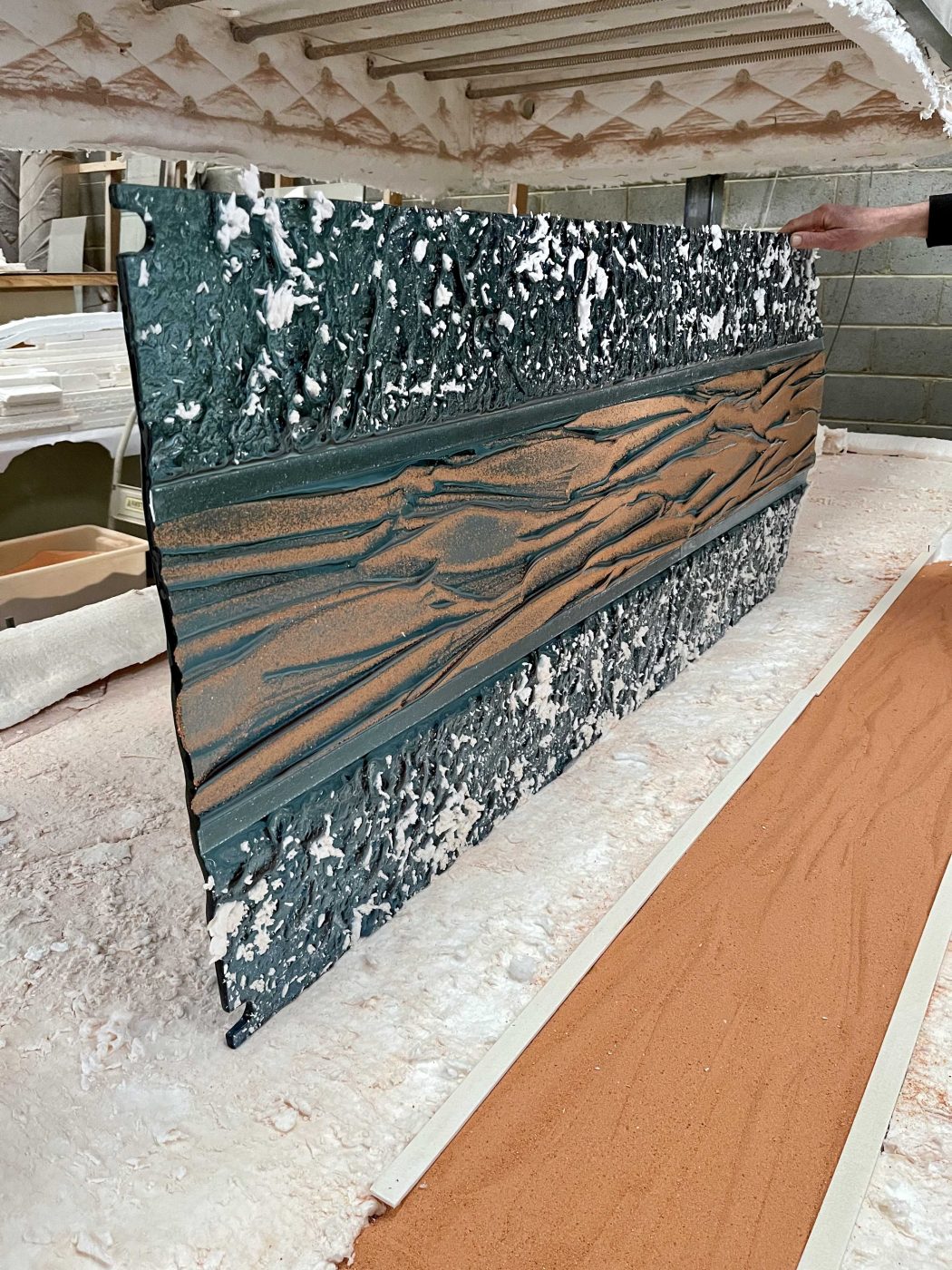

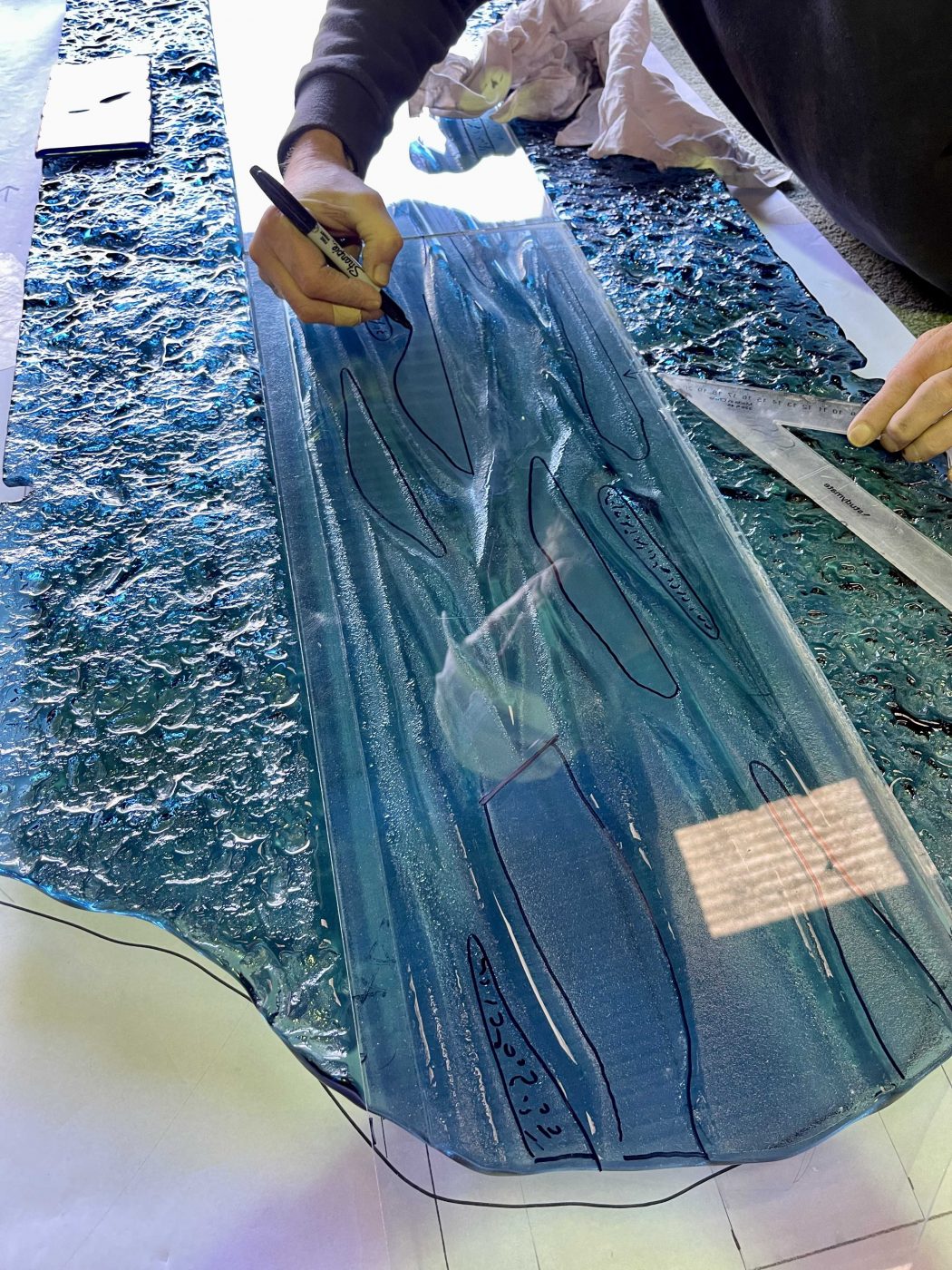

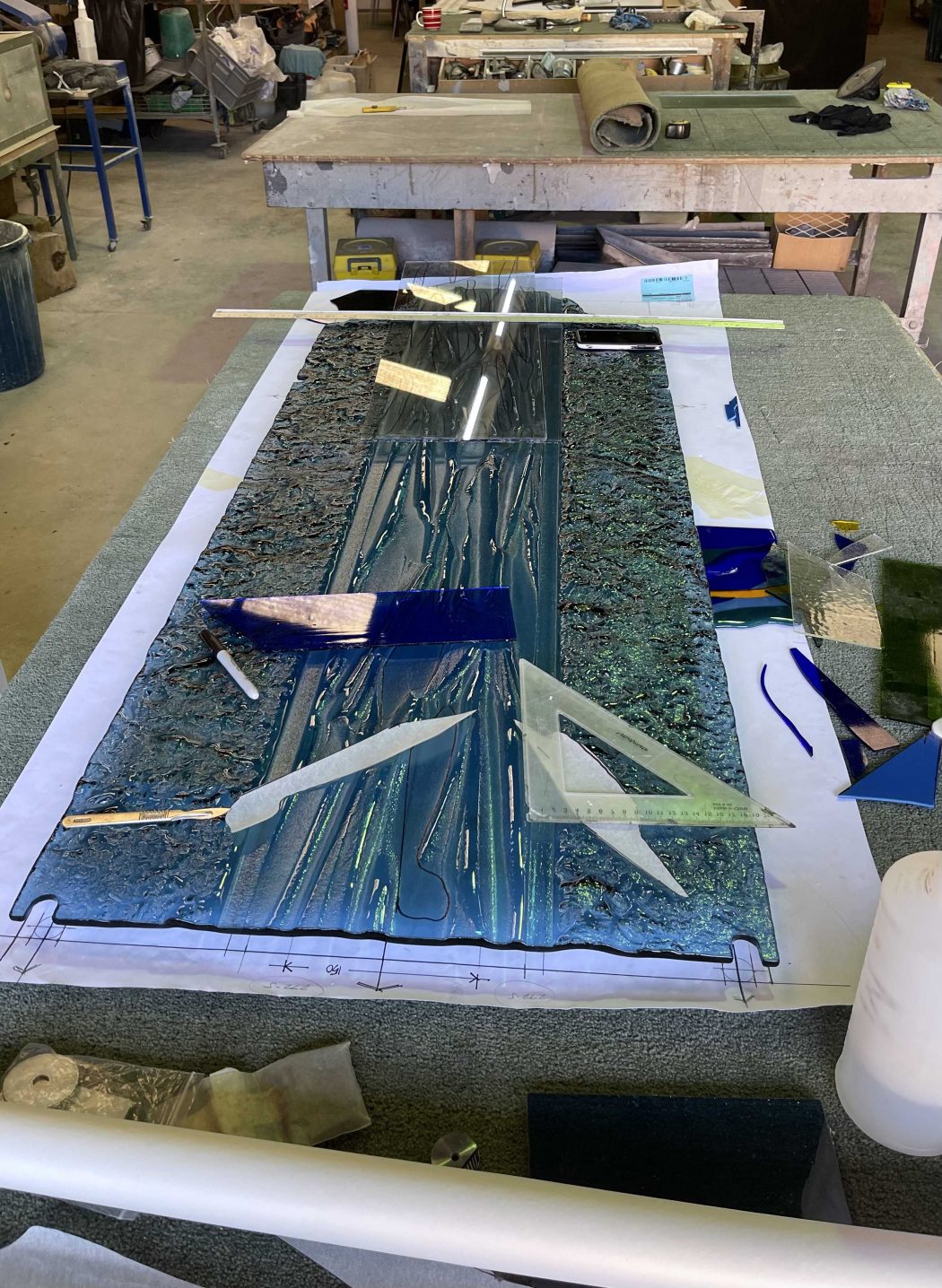

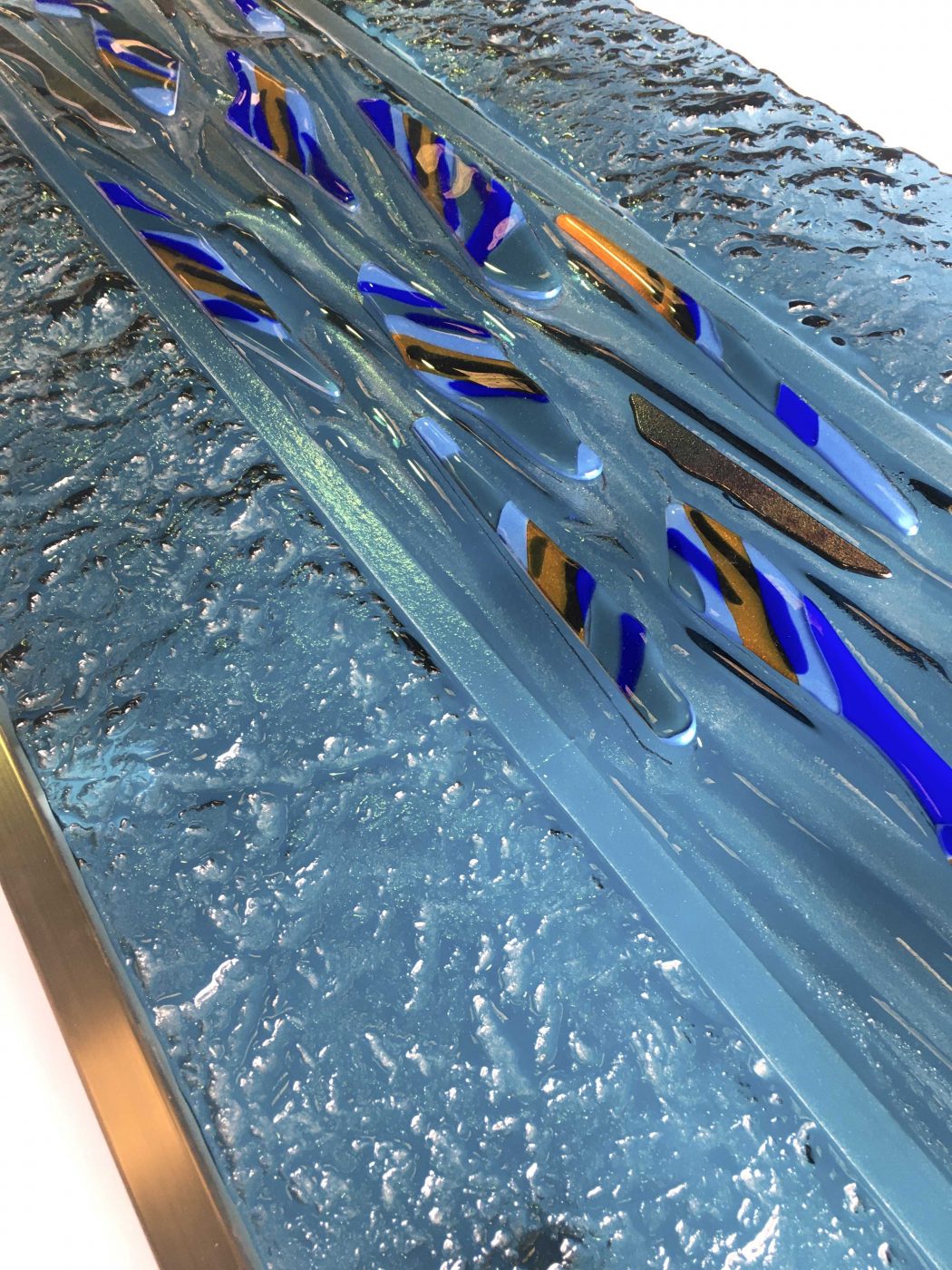

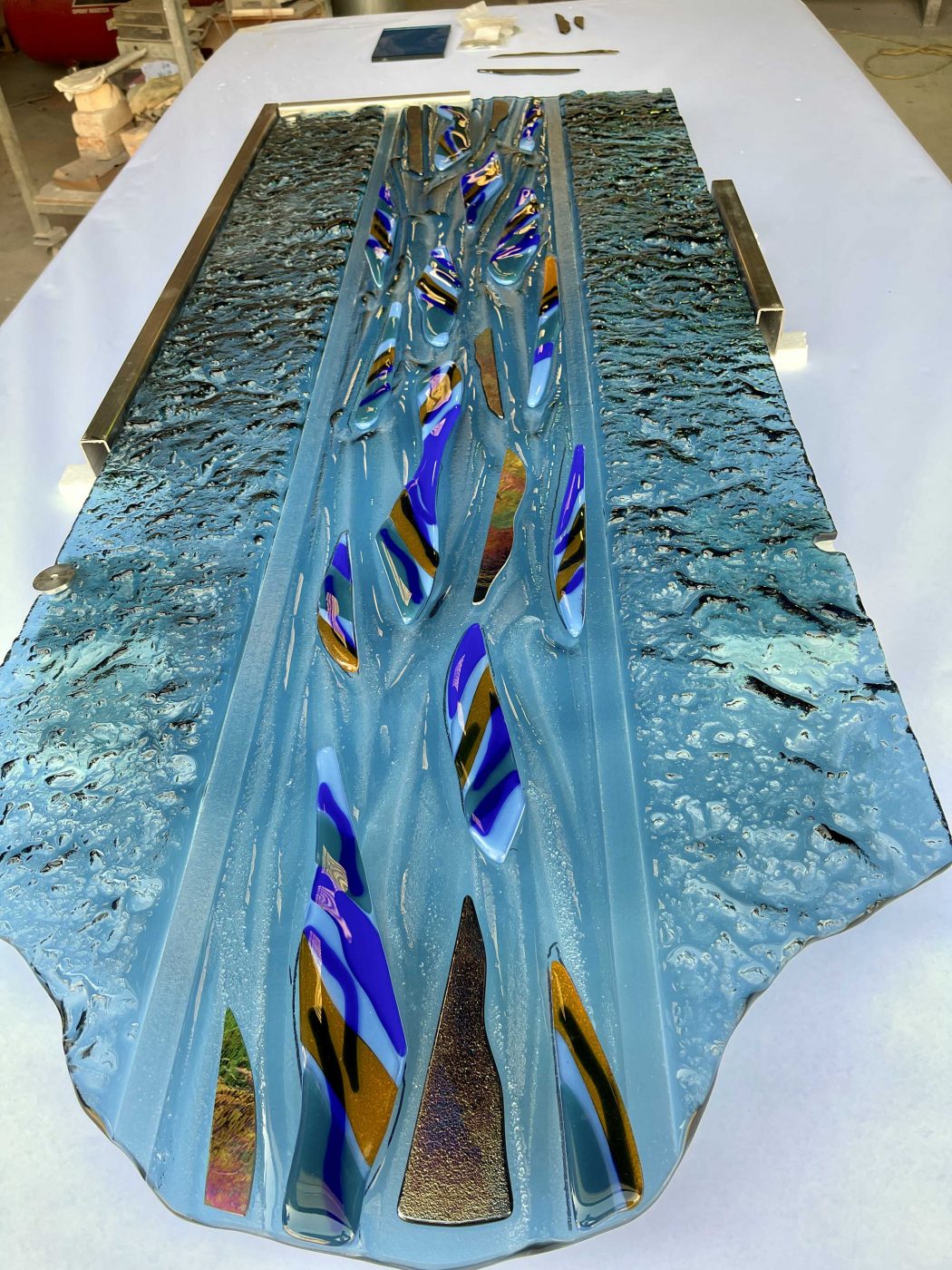

A work in progress, the design developed over time .. the original idea to have horizontal decorative hand cast pieces was replaced with vertical. The side sections were altered from vermiculite to a more random texture. ….

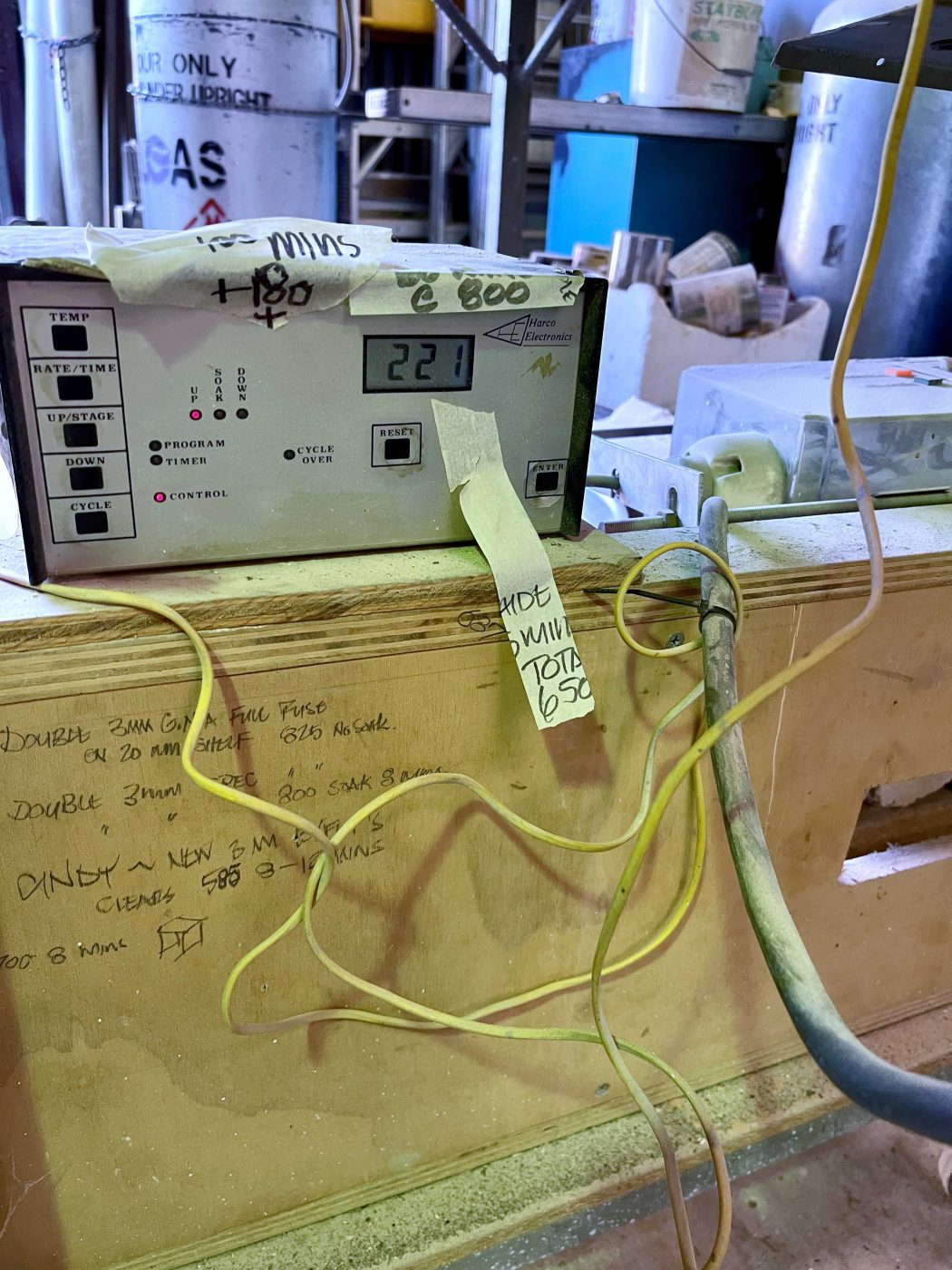

A few definitions to explain the technical aspect ….

Float Glass Float glass is extremely smooth, distortion-free glass made by pouring the molten glass from a furnace into a chamber that contains a bed of molten tin. The upper surface of the glass is called the air side or score side. It is polished with fire. The lower surface is called the tin side and is not fire-polished. From the chamber, the glass enters an oven, called a lehr. There it is slowly cooled a process called annealing that relieves the glass of internal stresses. Float glass is made up of 60% sand, 20% Lime Dolomite 20% Soda Sulphate + Cullate, which is adding broken glass to the batch

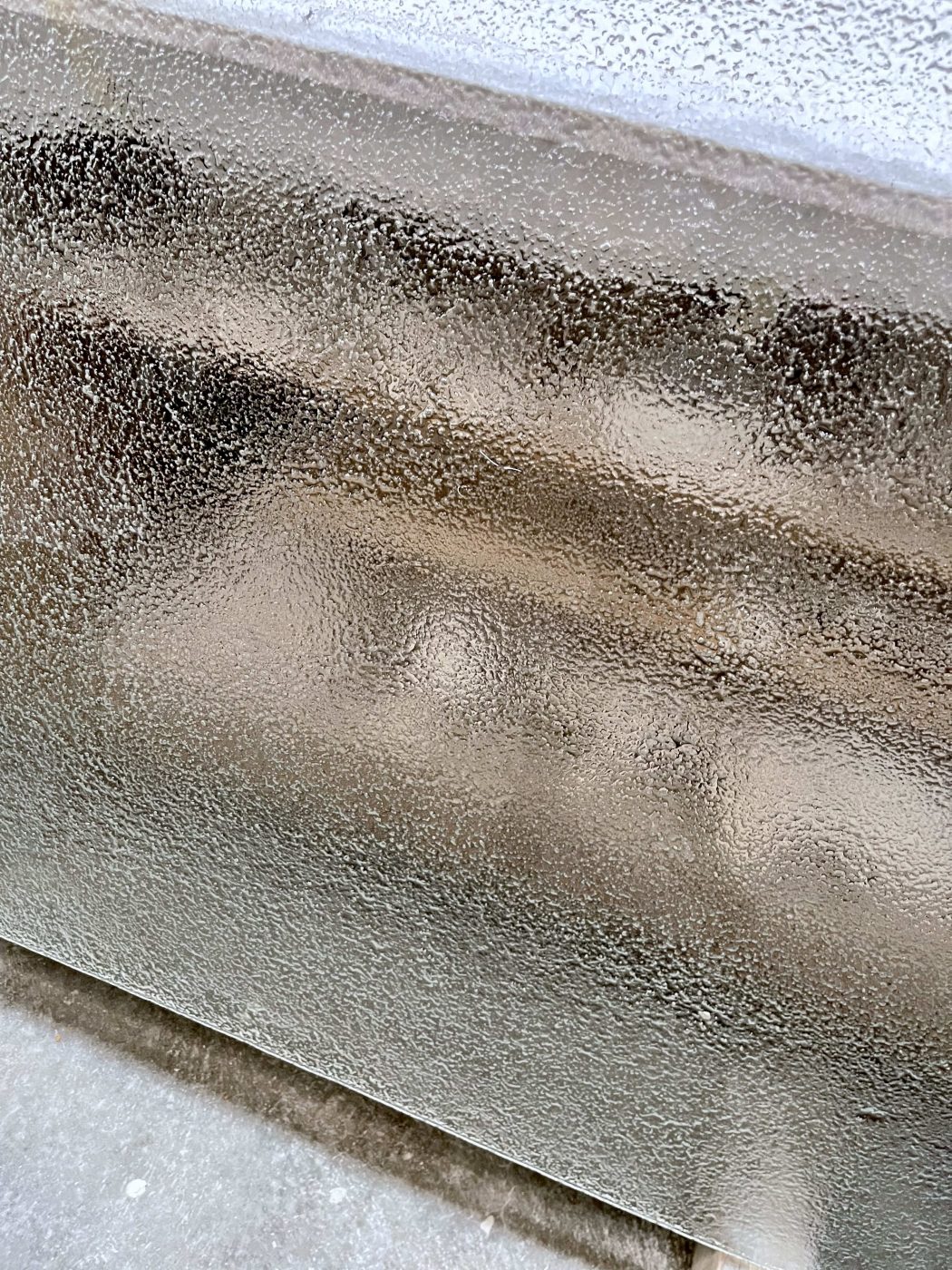

Slumped or Textured Glass is a process that uses gravity and heat from a kiln to shape sheet glass using a mould. The process of slumping, producing a texture, pattern or design into panels of glass involves stages of high heat to soften the glass into a molten almost toffee like consistency to melt into and over the pattern beneath it. It is then cooled in stages, returning the glass to a solid state with the pattern in place, leaving a textured side and a smooth glossy side with slightly rounded, fire polished edges.

Drape 650°C– glass softens enough to bend over a mould. Slump 675°C – glass softens enough to bend into a mold. Fire Polish 705°C – glass melts enough to produce a surface polish. Tack Fuse 732°C– pieces of glass will permanently fuse together.

Refractory Ceramic Fibre (RCF) Used in the kiln to create a mould for the glass. Sand was also used as a mould to create a pattern for the hand cast pieces.

Annealing is a process of slowly cooling hot glass objects after they have been formed, to relieve residual internal stresses introduced during manufacture

Click to view …. Waynne Detailing the Process & Technique

Toucan Forged Glass

(Rear) 686 Glen Huntly Road

Caulfield South 3162